In the world of electronics, the transition from a brilliant design to a physical, working product is often where the real challenge begins. Whether you are developing a life-saving medical device or a piece of high-performance industrial equipment, the quality of your PCB assembly (PCBA) is the heartbeat of your project.

At Cogent Technology, we don’t just “populate boards.” We provide a world-class PCB assembly service that bridges the gap between complex engineering and flawless manufacturing.

But what exactly sets a Cogent build apart from the rest? Let’s dive into how we manufacture your innovation.

The Secret Sauce: MaPS (Monitoring and Planning System)

Most assembly houses have a plan, but Cogent has MaPS. Unique to our facility, the Monitoring and Planning System is our proprietary digital backbone. It gives our team, and our clients, unrivaled control over the entire manufacturing journey.

From the moment your order passes through our PO Entry Gate, MaPS manages the work stack. It ensures that the right tools are on hand, training is up to date, and capacity is optimized. This isn’t just about efficiency; it’s about On-Time Delivery (OTD). By using live data to flag potential issues before they become delays, we provide a level of transparency that traditional manufacturers simply can’t match.

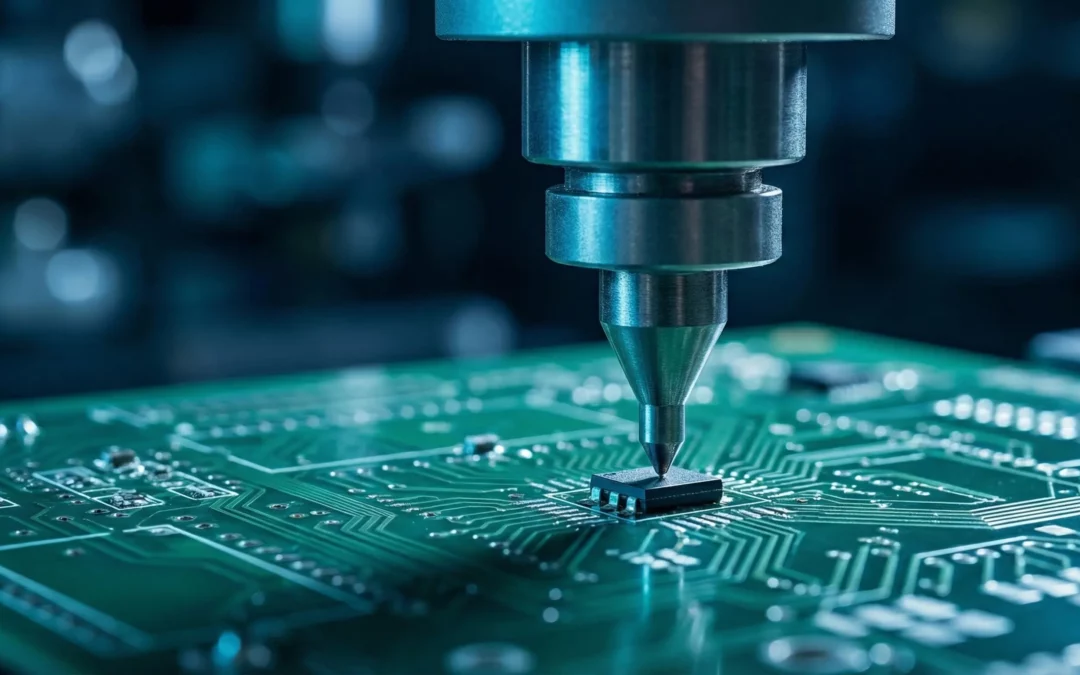

Precision Engineering: SMT, PTH, and Beyond

Modern electronics require a mix of speed and delicacy. Our PCB assembly service is built to handle the full spectrum of modern requirements:

- Surface Mount Technology (SMT): Our high-speed automated “pick and place” lines offer micron-level precision for even the smallest components.

- Plated Through-Hole (PTH): For components that need extra mechanical strength, we utilise Wave and Selective Wave Soldering.

- Mixed Technology: Most modern boards are a hybrid of both. We manage this complexity seamlessly, ensuring every joint whether hand-soldered or reflowed, is perfect.

Surface Mount Technology for PCB Assembly

Quality You Can Trace: IPC-A-610 Standards

In high-stakes industries like Aerospace and Medical, “good enough” doesn’t exist. That’s why everything we produce is governed by IPC-A-610, the international gold standard for electronic assembly acceptability.

We don’t just follow the standard; we live it. All our inspectors are trained and certified to these criteria, ensuring that every solder joint, component orientation, and board cleanliness level meets the rigorous requirements of your specific “Class” (from Class 1 to mission-critical Class 3).

A Path for Every Product

Every project is at a different stage of its life cycle. Our PCB assembly service is designed with three distinct routes:

Fast Track / Prototyping: For when you need to prove a concept and get to market yesterday.

NPI (New Product Introduction): Our “Hot House” process, where we refine your design for manufacture (DFM) to ensure it can be built reliably at scale.

Series Production: Full-scale manufacturing backed by a robust supply chain and rigorous functional testing.

Ready to Start Your Journey?

The difference between a “working prototype” and a “market-leading product” is the quality of the assembly. With Cogent Technology, you gain a partner invested in your success, backed by the most advanced planning system in the UK.

Looking for a reliable partner for your next project? Explore our PCB assembly service today and see how we can help you.

Cogent Technology

Tel: +44 (0)1394 445566

Email: enquiriescem@cogentcem.co.uk

Recent Comments